1. What is JENOLITE Welders Anti-Spatter Spray?

It is a non-flammable aerosol spray designed to protect surfaces against welding spatter. It prevents spatter from sticking to workpieces, reduces cleanup time, and preserves the integrity of your welding projects.

2. Which surfaces can it be used on?

- Metals and workpieces exposed to welding operations

- Any surface needing protection from spatter

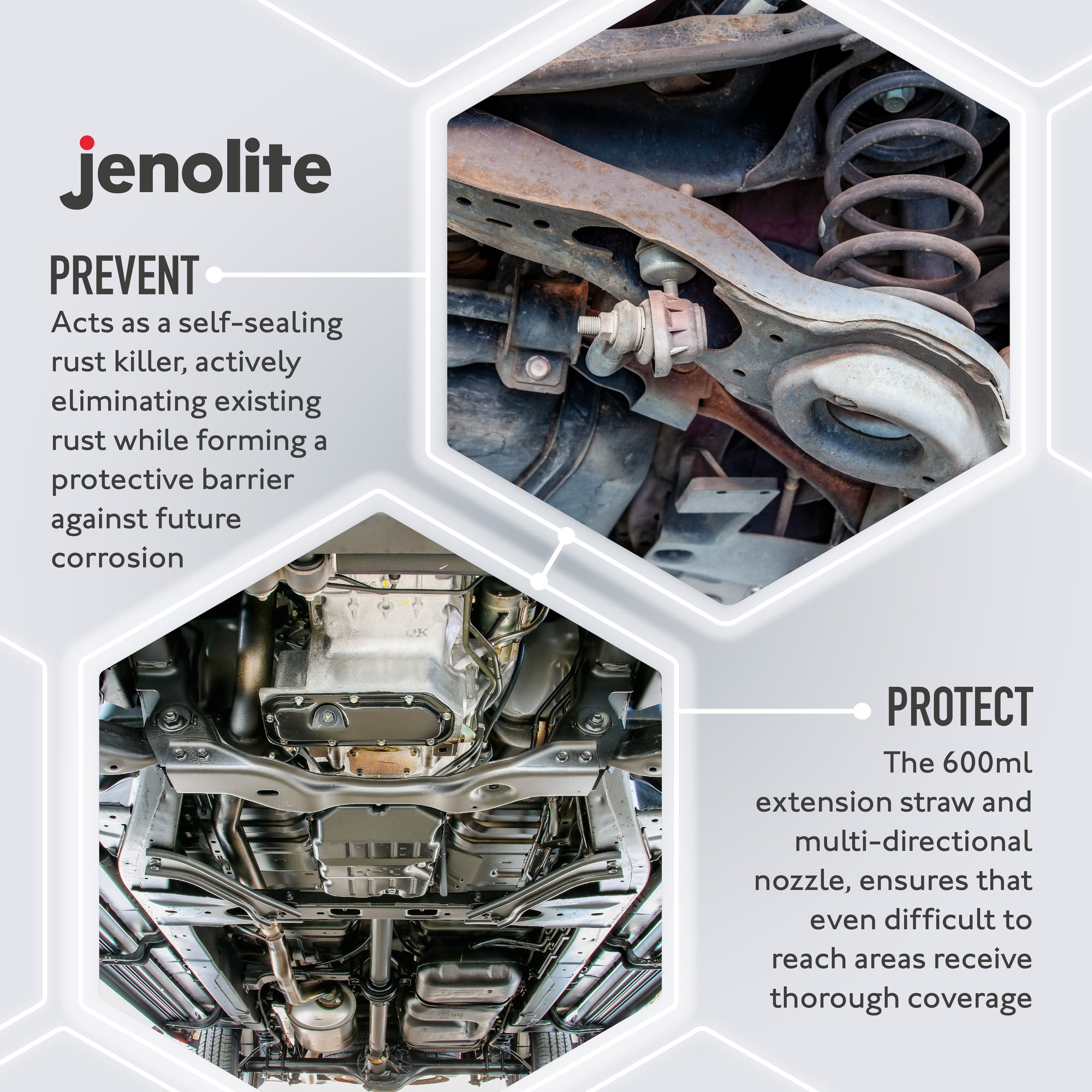

3. How does it protect surfaces?

- Prevents welding spatter adhesion

- Reduces cleanup time after welding

- Can be removed easily with a steel brush or water

4. Is it safe to use around heat or flames?

Yes. The formula is non-flammable, providing a safer environment during welding operations.

5. Does it contain silicone?

No. The spray is silicone-free, ensuring compatibility with subsequent coatings, paints, or treatments without affecting surface quality.

6. Is it corrosive?

No. The spray is non-corrosive, protecting your workpieces and equipment from harmful chemical reactions.

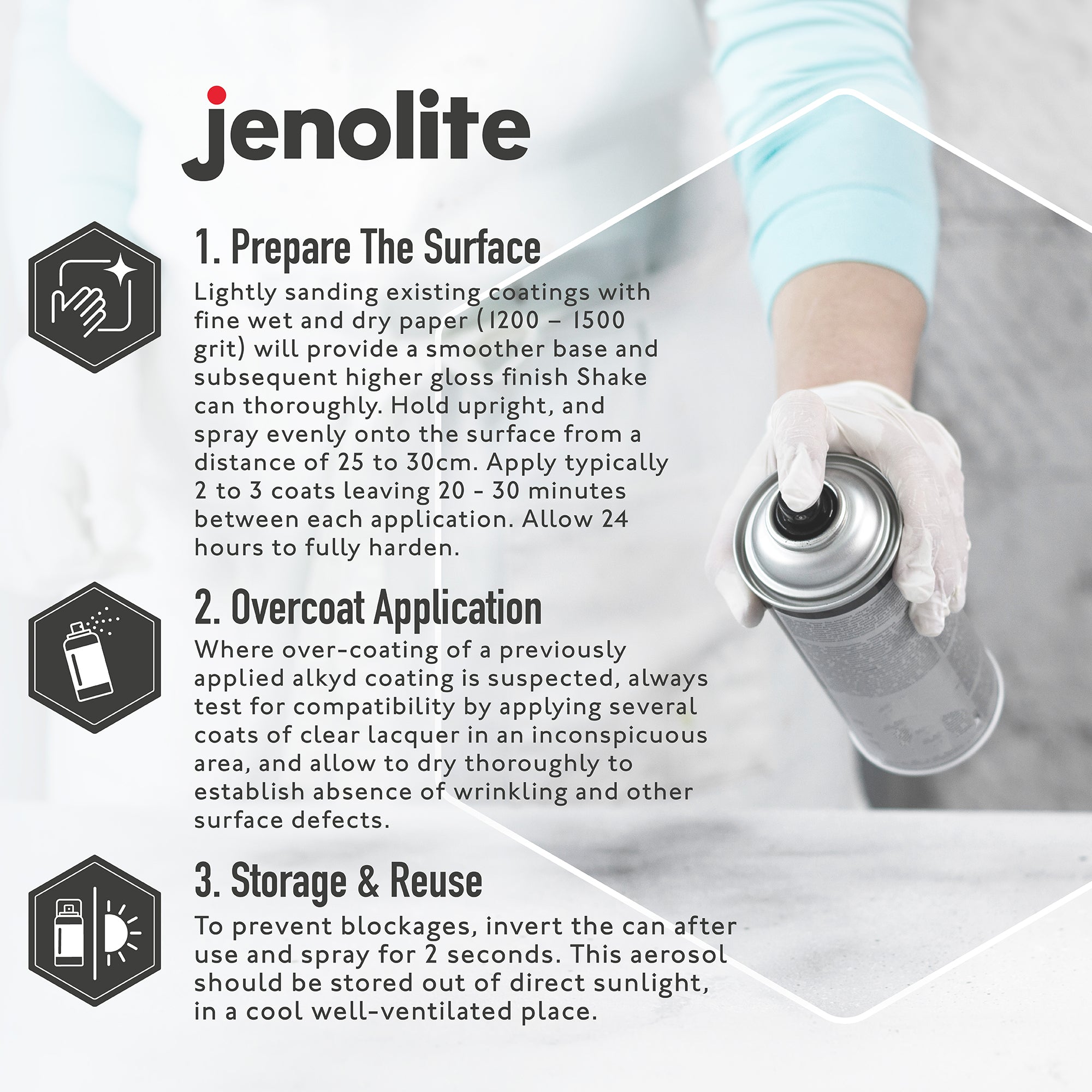

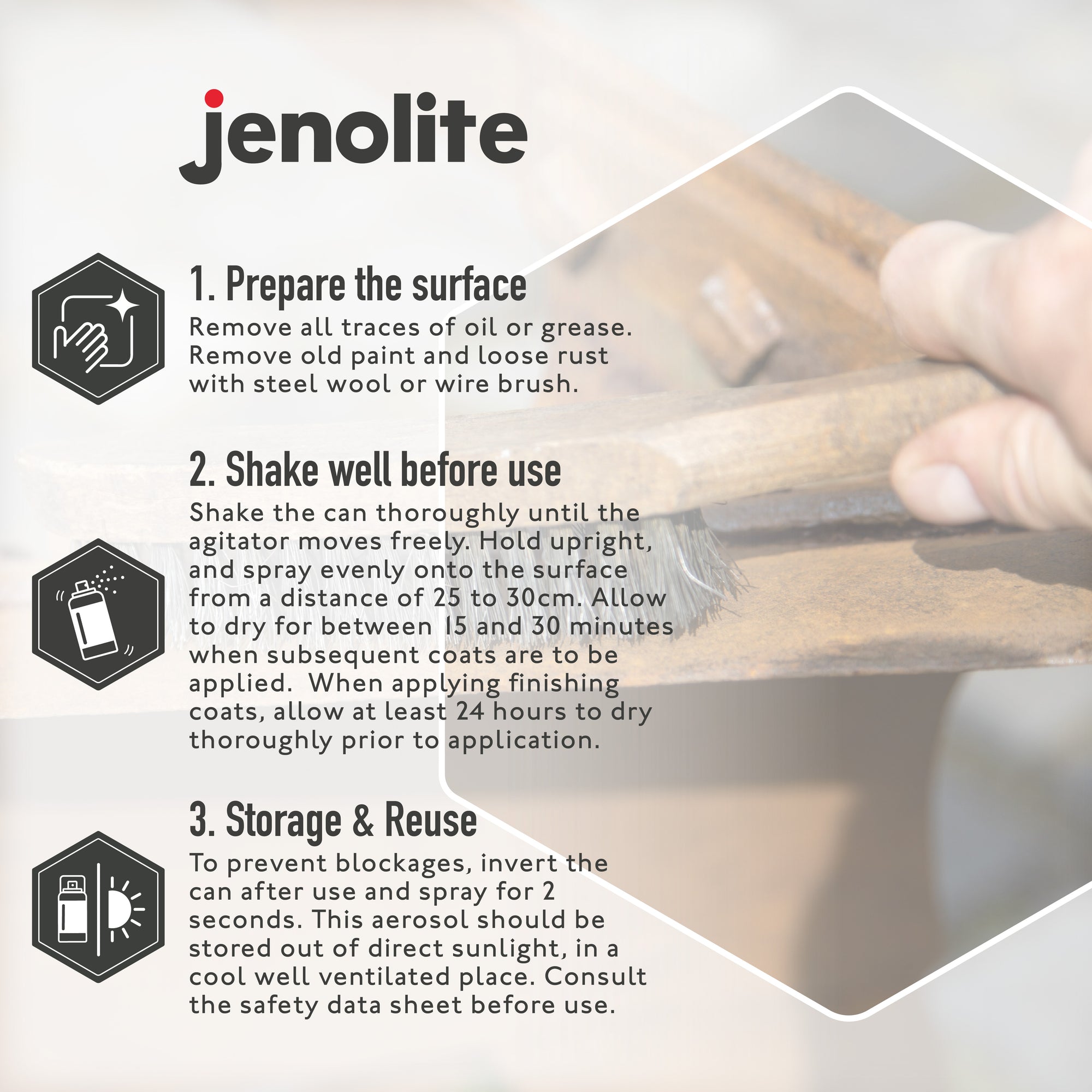

7. How do I prepare before use?

- Remove all traces of oil and grease using a suitable degreaser.

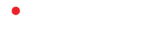

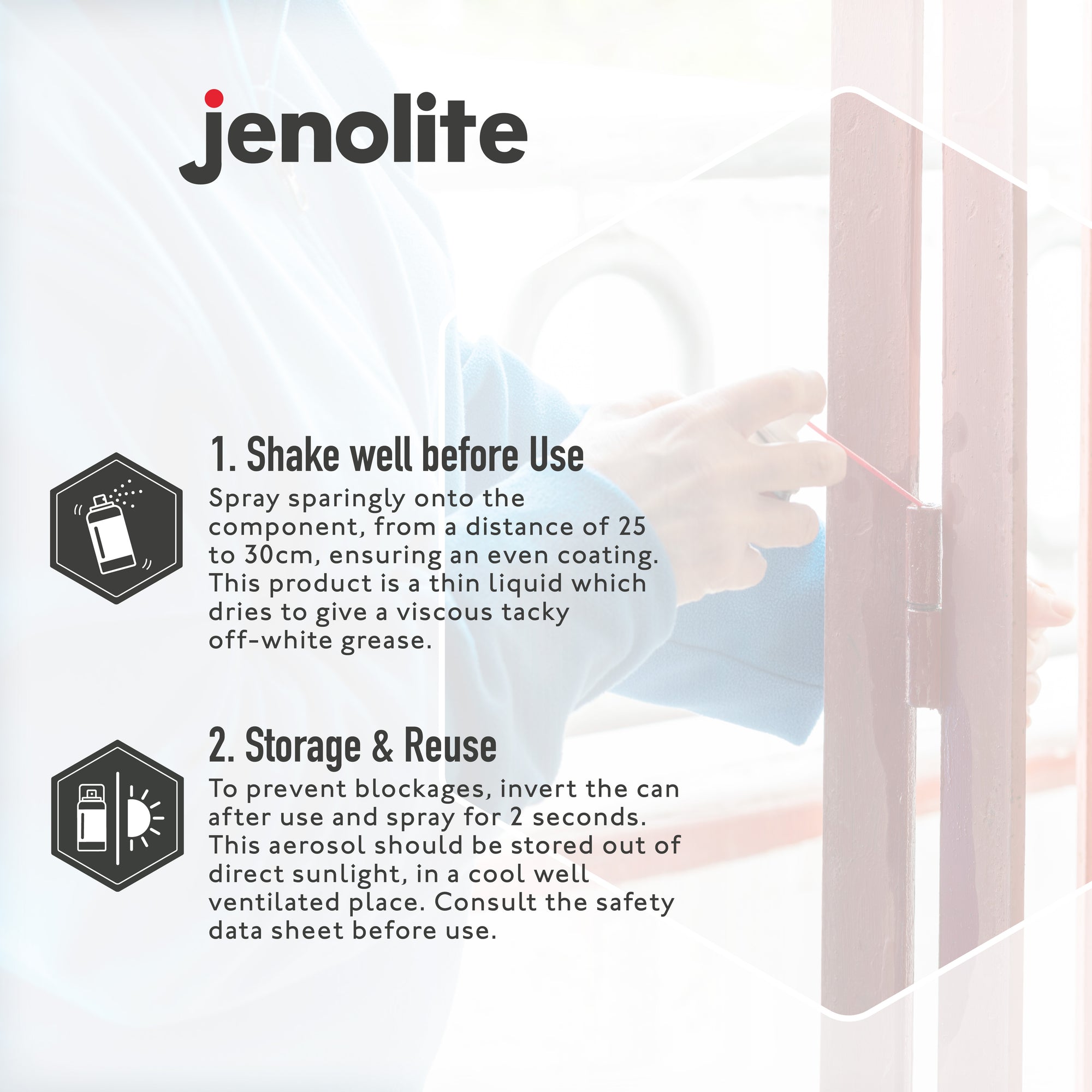

- Shake the aerosol can well before application.

8. How should I apply the spray?

- Spray generously on areas that need protection prior to welding.

- After welding, remove any spatter with a steel brush.

- Optional: remove residual oil with water or a damp cloth.

9. What are the ideal working temperatures?

- Minimum: 10°C

- Maximum: 25°C

- Best processing temperature: 5–35°C

10. How should I store and maintain the spray can?

- After use, clean the nozzle by turning the aerosol upside down and pressing for 5 seconds.

- Store in a cool, dry area, out of direct sunlight.

11. What projects is it ideal for?

- Welding protection for automotive, metal fabrication, and industrial projects

- Preserving surface quality during repetitive welding operations

- Reducing post-welding cleanup time

12. Is it safe to use?

Always follow the Safety Data Sheet (SDS) instructions. Use in a well-ventilated area and avoid prolonged inhalation of spray fumes.